A medical institution has concerns of alleged low voltage that affects operation of their medical equipment. Affected medical equipment are x-rays, ultrasound, CT scan, among others.

During an investigative interview with the admin, it was revealed that equipment failure occurs on random. But usually failures are more frequent during inclement weather.

Inspection of the electrical facility, especially the dry type transformer serving the institution, revealed poor grounding practice. The transformer has no grounding electrode and yet the medical equipment utilizes phase-to-neutral supply. Absence of this grounding electrode and proper bonding to the neutral may result to unpredictable voltage levels at the medical equipment power supply connection point. This condition aggravates during inclement weather or during fault conditions (either from the utility or other nearby end-users) near the vicinity of the medical institution. Figure 1 shows the dry type transformer serving the

Figure 1 . Dry type Transformer serving the Medical Institution

Power quality parameters monitored such as voltage regulation, harmonics, and voltage unbalance were within recommended industry limits. There were no transients recorded during the monitoring period.

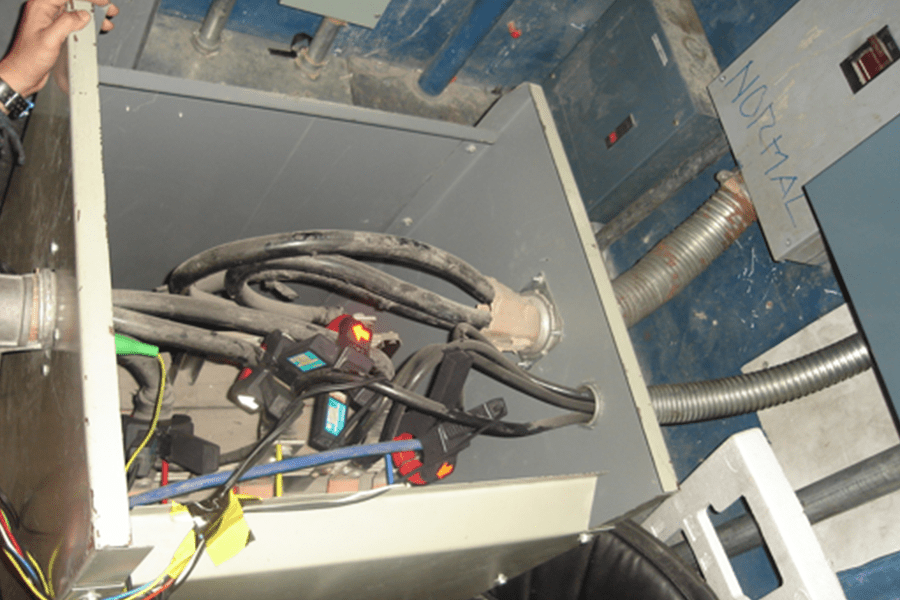

The likely cause of the medical equipment failure or malfunction can be attributed to poor grounding. To correct this problem, a Grounding Electrode (GE) must be installed and bonded to the transformer neutral and the Equipment Grounding Conductor (EGC). See Figure 2 for the actual recommended connection.

The medical institution was happy with the findings and recommendation. There has been no reported equipment failure or malfunction since 2007.

Figure 2. Recommended Grounding Configuration